CONTINUUMFLOOR

QUANTITY PER SQUARE METRE

Spruce screeds 20×40 mm, 3.50 lm

10 screws with cap

Steel screw with cylindrical/flat head 4×20 mm

7 self tapping screws

4 templates for the selected profile (supplied)

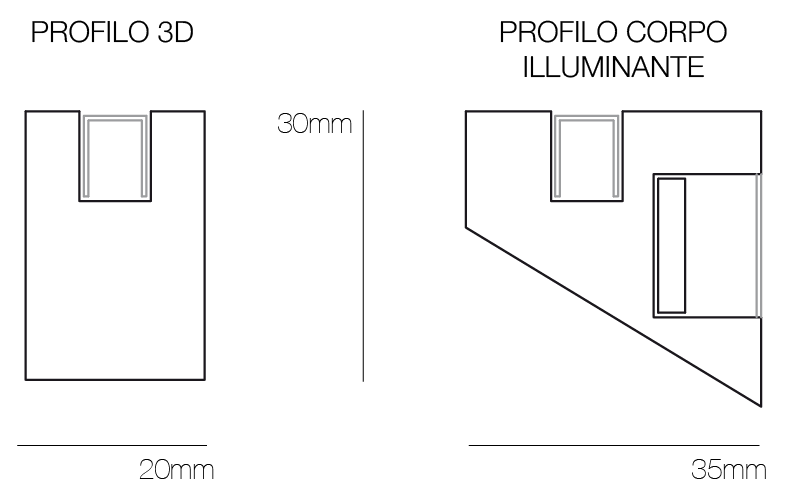

Connecting rail for 3D profiles:

• strip width 120 mm, 8.00 lm required

• strip width 150 mm, 6.00 lm required

• strip width 180/200 mm, 5.00 lm required

The material is calculated after removing 8-10% for waste.

FITTING

1- Lay the floor in scantling format, considering that the head of the horizontal element must correspond with the head of the vertical element.

2- Finish glue laying the floor in all the necessary rooms.

3- Now lay the structure scantling on the wall you have decided to coat using suitable steel screws and caps that comply with the wall. If you think it would increase indoor comfort, you can also fill the spaces with suitable insulating material (wood fibre, cork, etc.).

4- Continue laying the vertical elements, fixing them with a screw that passes through the plastic profile that acts as a support on the edge or a block that you have selected.

FITTING

1- Lay the floor in scantling format, considering that the head of the horizontal element must correspond with the head of the vertical element.

2- Finish glue laying the floor in all the necessary rooms.

3- Now lay the structure scantling on the wall you have decided to coat using suitable steel screws and caps that comply with the wall. If you think it would increase indoor comfort, you can also fill the spaces with suitable insulating material (wood fibre, cork, etc.).

4- Continue laying the vertical elements, fixing them with a screw that passes through the plastic profile that acts as a support on the edge or a block that you have selected.